News Highlights

- Two Fast Plasma Positioning Control Coils (FPPCs) for maintaining stable plasma during the plasma heating experiments scheduled to begin in 2026, have been completed for JT-60SA—the world’s largest superconducting tokamak— jointly constructed by Japan and Europe in Naka City, Ibaraki Prefecture.

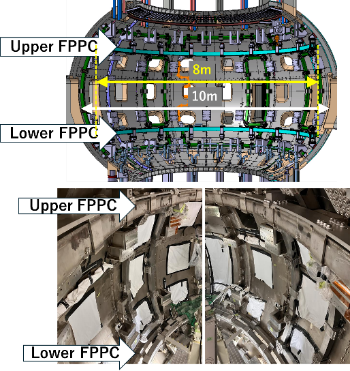

- The FPPC is an 8-meter-diameter copper coil, installed inside the JT‑60SA vacuum vessel (inner diameter 10 meters). During fabrication, engineers successfully overcame the technical challenge of winding coil within the confined environment of vacuum vessel, achieving positional and shape accuracy within ±2 millimeters.

- The technology developed with JT-60SA contributes to the fabrication of in-vessel coils for ITER, currently under construction in southern France. Going forward, the advanced technology for stable control of the world’s largest plasma using the FPPC at JT‑60SA will serve as an important foundation for advancing plasma control technologies amid intensifying international competition, and for establishing the autonomy and high reliability of DEMO reactors.

Summary

The National Institutes for Quantum Science and Technology (President: KOYASU Shigeo; hereinafter referred to as "QST") and Mitsubishi Electric Corporation (President & CEO: URUMA Kei; hereinafter referred to as "Mitsubishi Electric") have successfully completed the fabrication of two Fast Plasma Positioning Control Coils*1 (FPPCs)—a core technology for high-speed, high-precision plasma position control—for JT-60SA*² as part of the Broader Approach Activities*³, which is a joint project between Japan and Europe.

During its first plasma test in 2023, JT-60SA achieved a massive plasma volume of 160 cubic meters. In the upcoming plasma heating experiments scheduled to begin in 2026, the newly completed FPPCs for plasma control, with the goal of reaching a plasma current of 5.5million amperes (5.5MA).

Each FPPC is a copper coil measuring 8 meters in diameter, installed at two locations inside the JT-60SA vacuum vessel (inner diameter 10 meters). The current supplied to the FPPC—up to 5,000 amperes (5 kA)—is controlled at high speed within just 10 milliseconds, enabling precise regulation of the plasma’s position and shape. QST carried out the fundamental design of the FPPC’s performance and the in-vessel coil fabrication. Mitsubishi Electric subsequently devised new fabrication methods to realize this design, and through close collaboration, the two organizations successfully established the final coil positioning process. As a result, the FPPC was successfully completed with positional and shape accuracy within ±2 millimeters, which is a requirement to achieve stable plasma control.

The fabrication method developed in this project will contribute to the production of in-vessel coils for ITER*⁴, currently under construction in southern France. Furthermore, the plasma control using FPPC at JT-60SA will enable prior validation of the plasma control planned for ITER, serving as a foundation for advancing plasma control technologies amid intensifying international competition, and establishment of AI-driven autonomous plasma control. In this way, the successful completion of the FPPC marks an important step forward in advancing fusion energy research and development worldwide.

Completion of FPPC inside JT-60SA