Prototype divertor outer vertical target for the ITER fusion experimental reactor is completed and the sample has passed the ITER Organization’s certification test

Contributing to the realization of fusion energy which is expected to fundamentally solve energy and environmental issues using the technologies and knowledge of Hitachi and QST

- Rationalization of domestic production technologies and strengthening of the system in Japan for manufacturing divertor outer vertical targets for ITER

- Seeking to contribute to the ITER Project and provide components for the prototype reactor for fusion energy and startup machines

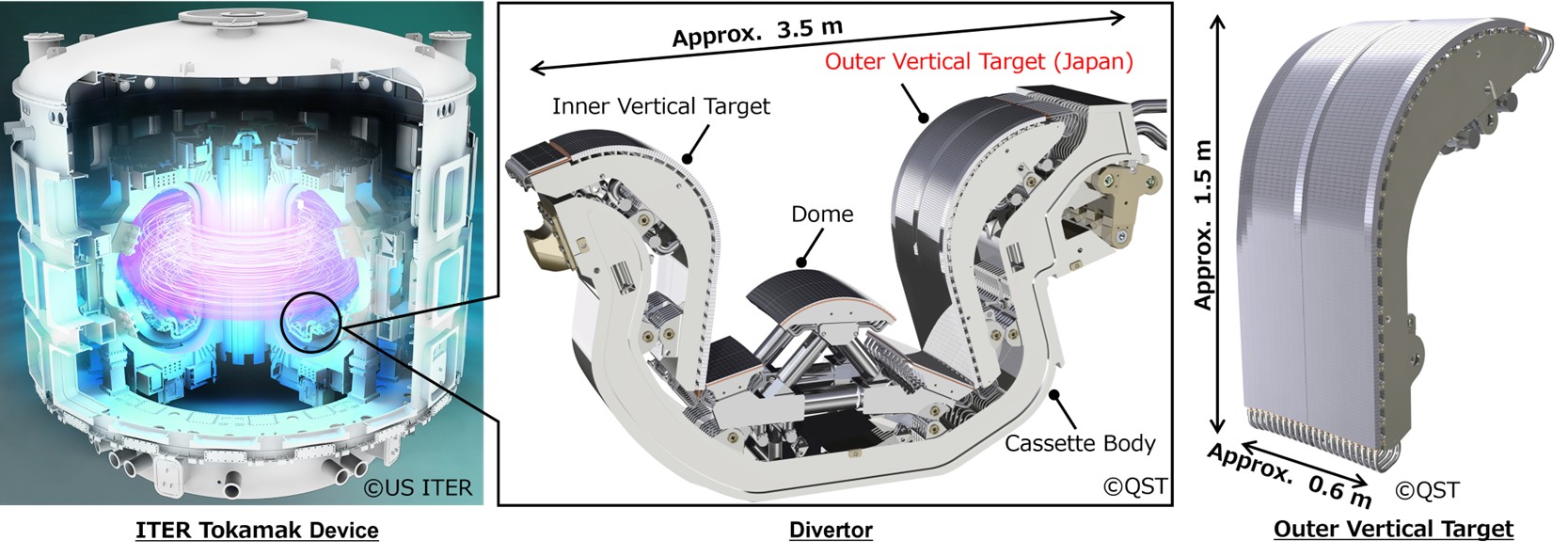

Tokyo, July 23, 2025 Hitachi, Ltd. (TSE:6501, "Hitachi") and the National Institutes for Quantum Science and Technology (“QST”) began developing a second prototype, a full-scale mockup of an outer vertical target*1 which is one of the most important components of a divertor in January 2022. Divertors are important pieces of components used in the ITER fusion*2 experimental reactor that is under construction in Southern France. With streamlining the production method through measures such as the introduction of an automatic welding system as detailed below, we completed the second prototype in March 2025. Furthermore, we today announce that a high-heat-load sample of an outer vertical target has passed the rigorous certification test by the ITER Organization, which constructs and operates ITER as an international organization. Hitachi’s production technologies have earned significant recognition following the preceding company which completed the first prototype with QST in July 2024.

*1 QST will deliver 58 outer vertical targets to the ITER Organization. The preceding company manufactured 18 of these. The company that will manufacture the remaining 40 targets will be decided later.

*2 Fusion is the source of the energy that keeps the sun shining. To realize fusion energy on Earth, it is necessary to use nuclear fusion reactions where deuterium, tritium and other light atomic nuclei fuse in a plasma state and become heavier atomic nuclei such as helium. Lithium, the raw material for tritium, and Deuterium are abundantly available in seawater. Additionally, the generation of fusion energy does not result in the generation of CO2. For this reason, fusion energy is expected to fundamentally solve energy and environmental issues. See *5 regarding plasma.

Utilizing the technologies and knowledge obtained through the production of the prototype, Hitachi and QST will continue to contribute to the promotion of the ITER Project and also cooperate in the development of technologies for realizing fusion energy in the future. In addition, Hitachi seeks to provide divertors and similar in-vessel components to fusion energy-related startups and a prototype fusion reactor for which QST is investigating the design.

The second prototype outer vertical target

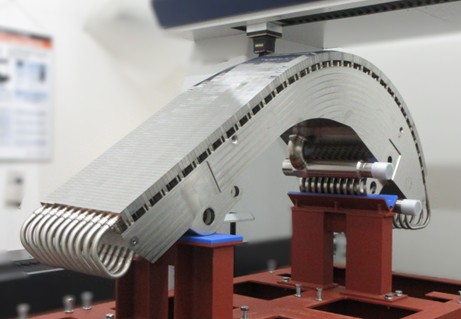

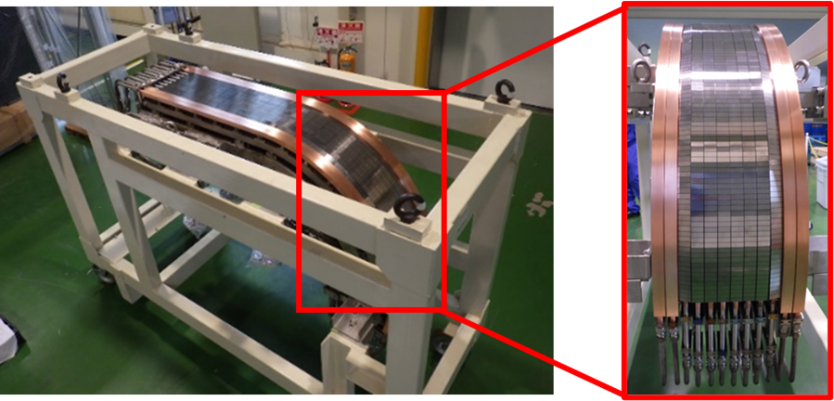

High-heat-load sample of an outer vertical target

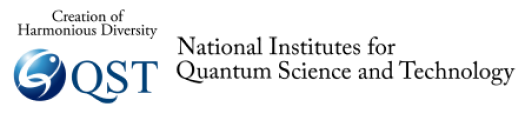

Outline of ITER and divertors

To realize fusion energy, seven regions including Japan, Europe, the United States, Russia, South Korea, China and India are promoting the ITER Project, a large international project aimed at conducting scientific and technological demonstrations of fusion. With the goal of achieving full operation through nuclear fusion burning, the ITER experimental reactor is under construction in Saint-Paul-lès-Durance, France. Japan is taking on important roles such as the development and production of major pieces of ITER components including divertors and toroidal field coils (TF coils). QST is the ITER Project’s agent in Japan and it promotes the procurement of equipment.

The divertor is one of the most important components of a tokamak*3 and other magnetic confinement*4 fusion reactors. Divertors play an important role in maintaining the stability of the nuclear fusion reaction and exhausting impurities such as fuel residue and the helium generated by the nuclear fusion reaction in the reactor core plasma.*5 Divertors are the only tokamak devices capable of directly receiving plasma. They are used in a severe environment where they are exposed to heat load and particle load from the plasma. For this reason, special materials such as tungsten are used to make them. Tungsten has a high-melting-point but it is difficult to machine. Moreover, the plasma-facing surfaces are precisely shaped, requiring high-precision machining and assembly technologies to achieve the correct overall shape, inclination, steps and gaps that are accurate to 0.5 mm or less. It is believed that divertors are the hardest piece of the ITER in-vessel components to manufacture.

*3 The method, represented by ITER and JT-60SA, retains an ultra-high temperature plasma that is more than 100 million degrees or higher within a strong magnetic field in a vacuum, and nuclear fusion reactions occur within the plasma. See *5 regarding plasma. See *11 for information about JT-60SA.

*4 Fusion plasma is at very high temperature and cannot be kept in a conventional container, but it retains positively or negatively charged ions and characteristically becomes entangled in magnetic fields (lines of magnetic force). Using these characteristics, a magnetic confinement fusion reactor forms a basket-like magnetic field to retain plasma.

*5 Plasma is one of the four basic states of matter. It is the fourth state next to solid, liquid and gas. When matter is exposed to very high temperatures or a strong electromagnetic field, atoms break down and separate to positively charged ions and negatively charged electrons, and they form plasma.

The heat load on divertors reaches a maximum of 20 megawatts per square meter. This is equivalent to the surface heat load that an asteroid probe is exposed to when entering the atmosphere and much more than the surface heat load the space shuttle was subjected to. Outer vertical targets need to have a strong mechanical structure because they are subject to strong electromagnetic forces that can reach an approx. maximum of 16.5 tons. The establishment of technology for making divertors resistant to high heat loads and huge electromagnetic forces is a very important part of increasing the power output of fusion reactors, reducing the size of the reactors or increasing their magnetic fields in the future.

Characteristics of the technology for the production of the second prototype

QST leads the manufacturers’ material development efforts, regarding them as key technology for enabling divertors to withstand heat load that can be as high as 20 megawatts per square meter. Consequently, the company established methods of producing tungsten monoblocks*6 which do not break even under heat load, and copper alloy cooling pipes which are kept strong by maintaining high thermal conductivity while limiting the coarsening of their crystal grain. To bond these materials together, a brazing*7 technology that is resistant to high heat load has also been developed.

*6 This is one of the components of the outer vertical targets that are a combination of tungsten, a metal that is resistant to heat load, and a copper buffer material.

*7 A method of bonding metals. The technology uses a metal called a brazing material to bond base materials to each other. In contrast, welding is a method of bonding metals by welding a base material.

By combining technologies and experience which are accumulated over many years in the nuclear energy business, Hitachi has developed a defect-free, high-quality welding technology for special materials and a non-destructive technology for inspecting restricted and complex shapes, and repeated demonstration testing has shown that Hitachi has achieved the high-precision machining and assembly technology that is accurate to 0.5 mm or less, a requirement of the ITER Organization. To rationalize production processes and costs, an automatic welding system optimized specially for divertors was introduced for welding thick, high-strength stainless steel. Instead of manual work, a robotic arm with a welding torch attached is combined with a device that controls the position of the object to be welded in synchronization with the movement of the robotic arm, resulting in higher quality welding at low cost.

The special materials necessary for outer vertical targets are procured by QST from material manufacturers and are supplied to Hitachi which uses the special materials provided by QST to machine and assemble outer vertical targets in a strictly quality-controlled process. QST maintains and uses a high-temperature helium leak test facility*8 for the in-vessel components of fusion reactors that is the only one of its kind in Japan, and it independently conducts final tests to ensure the quality of the divertors.

*8 The test facility uses helium gas to check for leaks with high precision at a high temperature of 250 °C which is the environment that divertors will be used in.

Initiatives implemented by Hitachi and QST to date

To date, Hitachi and QST have been developing and manufacturing an ultra-high-voltage power supply system*9 with a voltage of 1 million volts for neutral beam injectors*10 for ITER. Currently, a system is being tested in Italy. Production of the devices to be delivered to France has commenced at Hitachi’s factory. To realize fusion energy quickly, efforts are under way in Japan to reinforce neutral beam injectors for JT-60SA,*11 the world’s largest superconducting tokamak device built jointly by Japan and Europe in parallel with the ITER Project.

*9 The system supplies the power needed to actuate neutral beam injectors.

*10 The device for injecting high-energy hydrogen atoms into plasma to heat the plasma. It heats the plasma to an ultra-high temperature of more than 100 million degrees, the temperature at which a nuclear fusion reaction occurs.

*11 For information about JT-60SA, see the explanation about the JT-60SA Project on the website of the National Institutes for Quantum Science and Technology.

Website about Hitachi's fusion business

https://www.hitachi.co.jp/products/energy/nuclear/accelerator/index.html

About Hitachi, Ltd.

Through its Social Innovation Business (SIB) that brings together IT, OT(Operational Technology) and products, Hitachi contributes to a harmonized society where the environment, wellbeing, and economic growth are in balance. Hitachi operates globally in four sectors – Digital Systems & Services, Energy, Mobility, and Connective Industries – and the Strategic SIB Business Unit for new growth businesses. With Lumada at its core, Hitachi generates value from integrating data, technology and domain knowledge to solve customer and social challenges. Revenues for FY2024 (ended March 31, 2025) totaled 9,783.3 billion yen, with 618 consolidated subsidiaries and approximately 280,000 employees worldwide. Visit us at www.hitachi.com.

About the National Institutes for Quantum Science and Technology

The National Institutes for Quantum Science and Technology (QST) was established in April 2016 to promote quantum science and technology in a comprehensive and integrated manner. QST leads the world in 3 fields of research and development. Research on Quantum Technology Basis aims to create high functionality materials and devices utilizing high end laser technology. Research on Quantum Biological science aims to elucidate biological processes based on quantum science and technology. Research on Innovative Diagnosis and Treatment for Cancer and Dementia and other symptoms aims to realize a society of healthy longevity through heavy ion therapy, high precision diagnosis utilizing PET and treatments using targeted isotope therapy.

Furthermore, the operation and maintenance of 3GeV-class synchrotron radiation facility “NanoTerasu” will be conducted as a national center of core high radiation medical assistance with public-private partnership leading technical development and human resource development in radiation medicine. Visit us at https://www.qst.go.jp/

Contact information for Hitachi, Ltd.

Business Contact

Taku Oyama

Project Management Group

Fusion and Accelerators Development Center

Group Leader Senior Engineer

Hitachi, Ltd

+81-294-55-3420

taku.oyama.ke@hitachi.com

Contact information for National Institutes for Quantum Science and Technology

Business & Media Contact

QST International Affairs and Public Relations Section,

Department of International Affairs and Public Relations

+81-432-06-3026

info@qst.go.jp