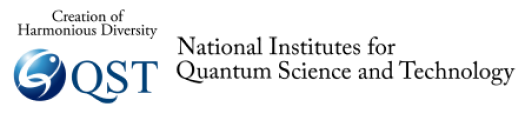

The radionuclide production is divided into two major processes: (1) target irradiation and (2) purification of product radionuclides. First, a target material is irradiated with a beam using an accelerator to produce radionuclides via a nuclear reaction, where various substances with different physiochemical properties need to be formed as an irradiation target and held in a beam spot. The design of target vessels and irradiation systems is crucial to achieve efficient and safe irradiation for any target substances. Second, radiochemical purification is performed to isolate radionuclides from the irradiated target. A scheme needs to be established to obtain radionuclides in any chemical form with a high purity and a high yield. Additionally, clinical application increases production frequency and quantity, resulting in a need to operate these production processes remotely using machines and reduce radiation exposure to workers.

Thus, in order to achieve safer and more efficient production of all radionuclides that are needed in the clinic and other scientific fields, our group is developing original irradiation devices, target vessels, purification schemes, remote operation systems, etc.

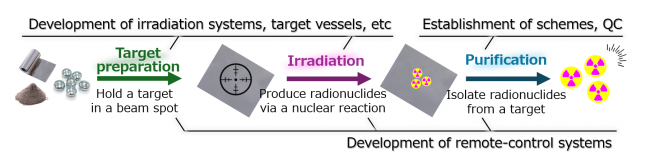

(1) Development of irradiation stations and target vessels to enable irradiating a variety of target materials

Foils or sealed gases/liquids are commonly used as target materials for irradiation. Unfortunately, it is difficult to irradiate powders and granules, low-melting-point substances, volatile materials, etc. To make such irradiation safer and easier, we have been developing unique irradiation systems and target vessels, such as a vertical irradiation station and ceramic target vessels. 1),2),3) The vertical beam system and its target vessel enable irradiating powder/granule substances that are directly put on the target vessel. If necessary, targets are formed and prepared by electrodeposition, fusion-solidification, or crimp may be performed.

1) Nagatsu et al. Appl Radiat Isotopes 94, 363–371 (2014)

2) Nagatsu et al. Nucl Med Biol 39(8), 1281–1285 (2012)

3) Nagatsu et al. Appl Radiat Isotopes 69(1), 146–157 (2011)

(2) Development of production method for the unique radionuclides used in radiopharmaceuticals

To use the produced radionuclides for radiopharmaceuticals, they have to be isolated from the target. The radiochemical purification method is crucial to obtain radionuclides with a high purity of the expected chemical form in a high yield. In many cases, the target radionuclide is produced directly in a target via a nuclear reaction, purified from the target by dry distillation, or a wet process such as chromatography, extraction, etc., and then used for radiosynthesis. Additionally, we are developing a generator device that can repeatedly obtain daughter radionuclides produced from the radioactive decay of parent radionuclides. (Parent radionuclides are retained in a column and daughter radionuclides can be eluted easily from the column.)

(3) Production of Ac-225

Alpha particles have been attracting attention in recent years for their therapeutic effects that are superior to beta particles that have been used in nuclear medicine therapy up to the present. For one of the promising candidates, 225Ac (half-life: 10 days), the demand has rapidly increased, and as clinical applications of 225Ac have progressed, it has become more difficult to obtain 225Ac. We have successfully established a 225Ac production method using a 226Ra target, and are currently improving the production process to achieve clinical-scale production on the order of ~101 MBq.

4) Nagatsu et al. Ejnmmi 49, 279–289 (2021)

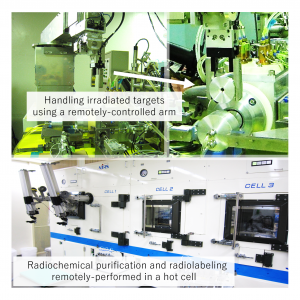

(4) Development of remoTely controlled systems for mass production of radionuclides at the clinical scale

In order to routinely produce GBq-order radioactivity for clinical use, we have also developed remote-handling equipment and maintained them for over a decade. In the 64Cu production, we use a remotely operated arm to retrieve irradiated 64Ni targets from the irradiation station. The targets are automatically transported to the inside of the hot cell by trolley. The purification and radiolabeling are also performed in the hot cell using a remote-controlled arm, leading to little radiation exposure to the operator.

In order to routinely produce GBq-order radioactivity for clinical use, we have also developed remote-handling equipment and maintained them for over a decade. In the 64Cu production, we use a remotely operated arm to retrieve irradiated 64Ni targets from the irradiation station. The targets are automatically transported to the inside of the hot cell by trolley. The purification and radiolabeling are also performed in the hot cell using a remote-controlled arm, leading to little radiation exposure to the operator.