- Withstand heat

- embedded cooling channel

- use Cu heat conductor

- Withstand Electro-magnetic force

- make the structure rigid

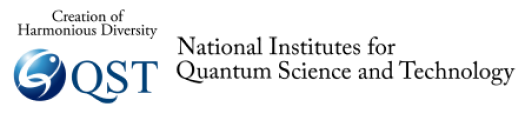

We applied Hot Isostatic Pressing (HIP) joining technique to the large scale structure for the first time.

Hot Isostatic Pressing (HIP) joining technique is one of diffusion bonding techniques in which parts are assembled tightly and pressed by the high pressure up to several hundereds MPa and heated to the temperature where the metal atom diffusion occurs frequently and parts are bonded to one pie

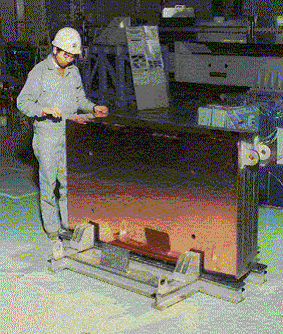

Succeeded in fabricating the word's largest bimetal structure by HIP joining !

Size : width 1.6m, height 1m, thickness 0.4m. Stainless tube cooling channels are embedded in the nearest Cu heat conductor region of the first wall which faces to the plasma, joined in near-net shape by HIP joining technique under 1050 deg-C, 150 MPa for 2 hours. By developing the HIP joining technique, one time HIP can bond 3 different parts.

Parts of the Blanket Module

Fabricated Blanket Module Prototype

Spin off to the Industrial Use

The HIP joining technique for large scale structure components are applicable to the general industrial use as follows.

Examples

Aircraft engines, Combustion room of gas turbine, Golf head, Artificial bone parts.

- Blanket Technology

- Shield Blanket

- Fubctional requirements

- Power Generation Blanket

- wall panel mockup

- References

- Fusion Engineering Research TOP