Introduction of Research Department

The department of Quantum Applied Photonics, a new research department established on April 1, 2023, develops cutting-edge technologies in laser applications for quantum technology (materials, life), medicine, and safety and security technology.

This department is clearly set forth the application of lasers (quantum optics) to quantum technology in a wide range of scientific and technological fields that have been cultivated by KPSI, and to consider contributions to quantum science and technology using lasers and the realization of social implementation in industrial and medical fields using lasers.

Research Projects

- Laser Driven Ion Accelerator Development Project

- X-ray Ultrafine Structure Processing Project

- Ultrafast Electronic Dynamics Project

- Medical Laser Applications Project

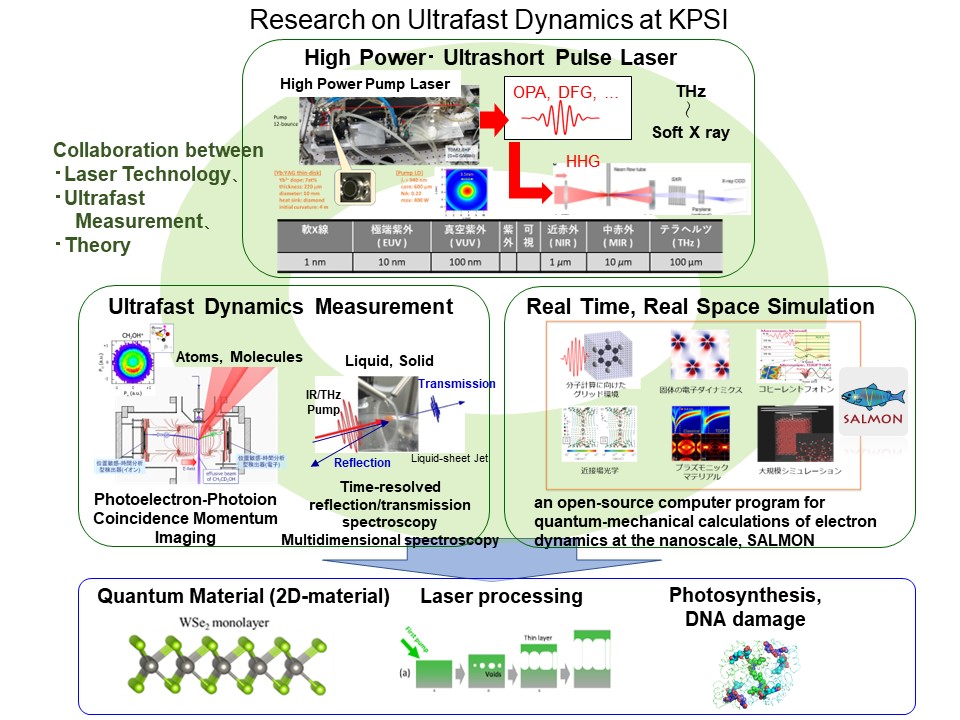

Development of a quantum scalpel using laser acceleration technology

QST is undergoing heavy-ion cancer therapy as a gentle and well-tested radiation cancer treatment. Heavy-ion cancer therapy is characterised by its high biological effect and local irradiation, and its effectiveness in treating, for example, unresectable pancreatic cancer has been confirmed to be high enough. On the other hand, heavy-ion cancer therapy requires a large accelerator to produce heavy-ion beams with sufficient energy for treatment, and its miniaturisation is a challenge for its widespread use. As part of the QST Innovative Project, QST is developing a next-generation heavy-ion cancer therapy device (Quantum Scalpel) using superconducting accelerator technology and laser acceleration technology to realise a downsized device. In this context, the Kansai Photon Science Institute is developing a laser-driven injector as an injector for the Quantum Scalpel by utilising its research and development capabilities in advanced laser acceleration technology.

Ion beam of several to several tens of MeV per nucleon can be obtained by irradiating a target such as a thin film or gas with an ultrashort high peak power laser. The Kansai Photon Science Institute has conducted research and development using an PW-class ultrashort high peak power laser (J-KAREN-P). The research and development of a laser-driven ion accelerator is being carried out to further develop this ultrashort high peak power laser technology and laser driven ion acceleration technology, aiming at a significant downsizing of the currently used heavy-ion accelerators by realising a smaller size and more stable operation. In the "Development and Demonstration of a Laser-driven Quantum Beam Accelerators" project of the Japan Science and Technology Agency (JST), a proof-of-concept study of a laser-driven ion accelerator that is an injector of a next-generation superconducting synchrotron is being conducted.

"Laser-driven ion accelerator as a injector for Quantum Scalpel" (prototype image #JST Future Society Creation Project)

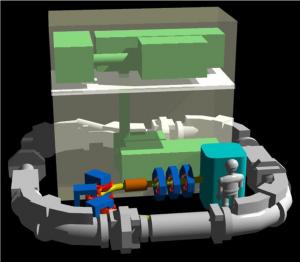

Research and Development of Surface Micro-fabrication Technology Using Coherent Soft X-rays

When a short-pulse laser beam is irradiated on material surface, the irradiated area vaporizes, and the atoms and molecules are scattered from the surface. This phenomenon has been known as ablation. We have performing various ablation experiments using a short-pulse soft x-ray laser at IMR. With the laser technology, we have successfully produced a hole structure with the depth of 2 nanometer on silicon surface. In this way, soft x-ray laser ablation can be applied to the surface processing, which will be useful for making nanometer-sized structures on the surface of various materials.

In our project on X-ray Ultra-fine Structure Processing, we are developing the surface-processing technology using soft X-ray lasers. In order to realize nano-fabrication of material surfaces, we are developing the following three technologies. (1) high-power coherent soft x-ray sources. (2) laser processing technology and hologram drawing technology; the former can be used to fabricate nanometer-deep shallow holes and nanometer-wide narrow grooves, and the latter can be used to measure the spatial coherence property of soft x-ray lasers. (3) time-resolved measurement technology; it can be used to elucidate the structure-formation process in laser material processing.

Figure: Ablation structure on silicon formed by soft x-ray laser

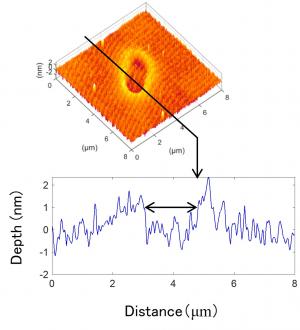

Ultrafast Electronic Dynamics Project

Structure and dynamics of materials at the atomic level are governed by electrons within the materials. Electronic dynamics is a decisive factor in chemical reactions. At Kansai Photon Science Institute, we are conducting a project aimed at clarifying the structure and dynamics of such electrons and at controlling them. Our research targets include various ultrafast phenomena such as electronic dynamics in atoms and molecules in laser fields, electronic excitation processes by intense laser irradiation on solid surfaces that lead to laser non-thermal processing, photoexcitation processes of functional materials called quantum materials, and chemical reactions in biomolecules such as photosynthesis and DNA damage.

In ultrafast dynamics research, ultrashort-pulse laser technology and ultrafast dynamics measurement techniques that utilize are tightly correlated to each other. Theoretical investigation is also important to understand and control ultrafast dynamics, since it is essential to interpret the observed results and to clarify physical mechanisms behind them.

In Ultrafast Electronic Dynamics Project of Kansai Photon Science Institute, we are developing (1) ultrashort light sources in all wavelength regions from terahertz to soft x-rays, (2) time-resolved spectroscopy and imaging techniques for observing ultrafast phenomena, and (3) theory and first-principles calculation for clarifying the light-matter interaction on the nano scale, cooperatively.

We welcome collaborative studies with other groups.

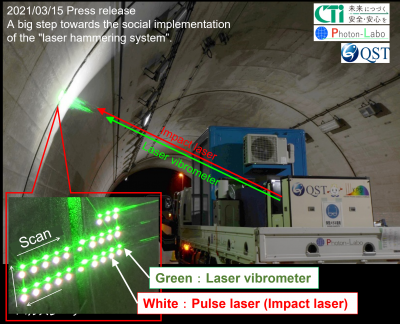

Development of remote-sensing technology for detection of defects inside concrete

As much of Japan's social infrastructure is approaching difficult levels for safe use after more than 50 years of construction following a period of rapid growth, the development of various inspection technologies for infrastructures is in progress.

The laser hammering system is new inspection device by using a high-power laser that remotes and digitizes hammering test. It has been developed through “Cross-ministerial Strategic Innovation Promotion Program (SIP 1st stage:2014-2018, 2nd stage:2018-2022) led by Cabinet Office” and “new conference of road technology / technology research and development that contributes to improving the quality of road policies (2021-2022) led by Ministry of Land, Infrastructure and Transport (MLIT)”.

The laser hammering system was jointly developed by QST and Photon-Lab Co. Ltd. certified venture company of QST. It was registered in the Performance Catalogue of Inspection Support Technology of MLIT in June 2020 (registration number: TN020003-V0323).

We are improving inspection speed by joint research with construction consulting companies and inspection companies that perform actual tunnel inspection work, and we are proceeding with the evaluation of concrete defects by the laser hammering method using concrete specimens.

In addition, we are developing remote sensing technology that takes advantage of characteristics of lasers such as small device and long-distance device for widely use.

Photo: Demonstration of inspection support work by using laser hammering system