Fusion Reactor Material Research

Still, a lot of research and development (R&D) must be achieved for an early realization of fusion reactor power plant. In our department, we are mainly conducting R&D on a variety of materials that will be the structural components of a fusion reactor and on the irradiation experimental facility . Although there are many types of materials to be studied for different reactor components, in our institute, the main targets are ferritic steels for blanket and divertor components, SiC/SiC composite for functional materials, copper alloys for heat sink and cooling channel materials, and tungsten for the parts that will suffer from high heat load.

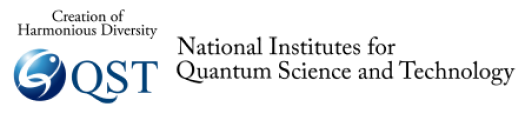

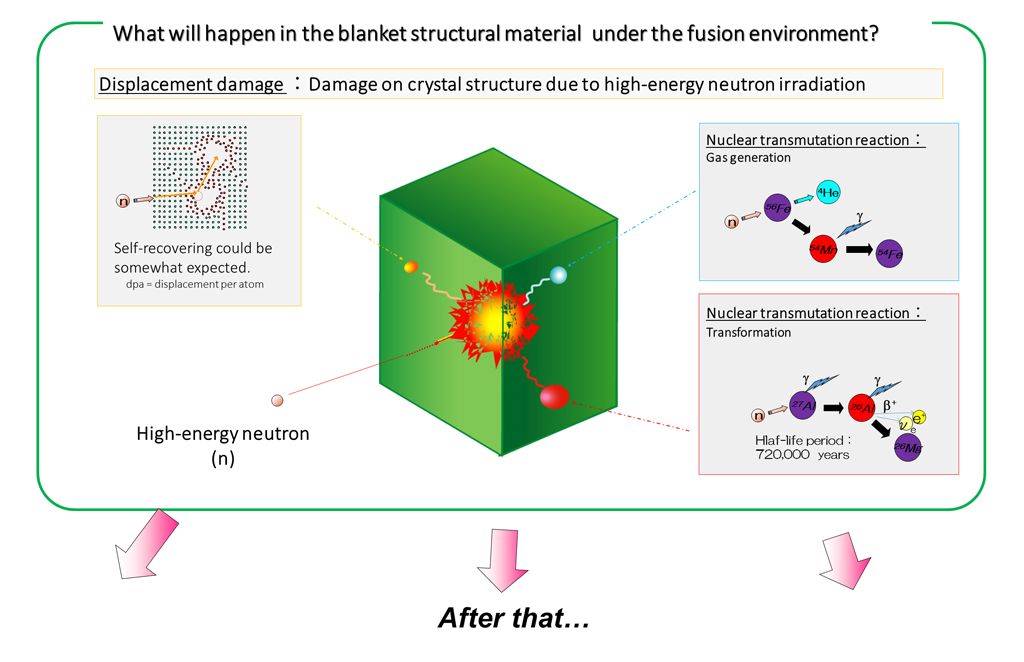

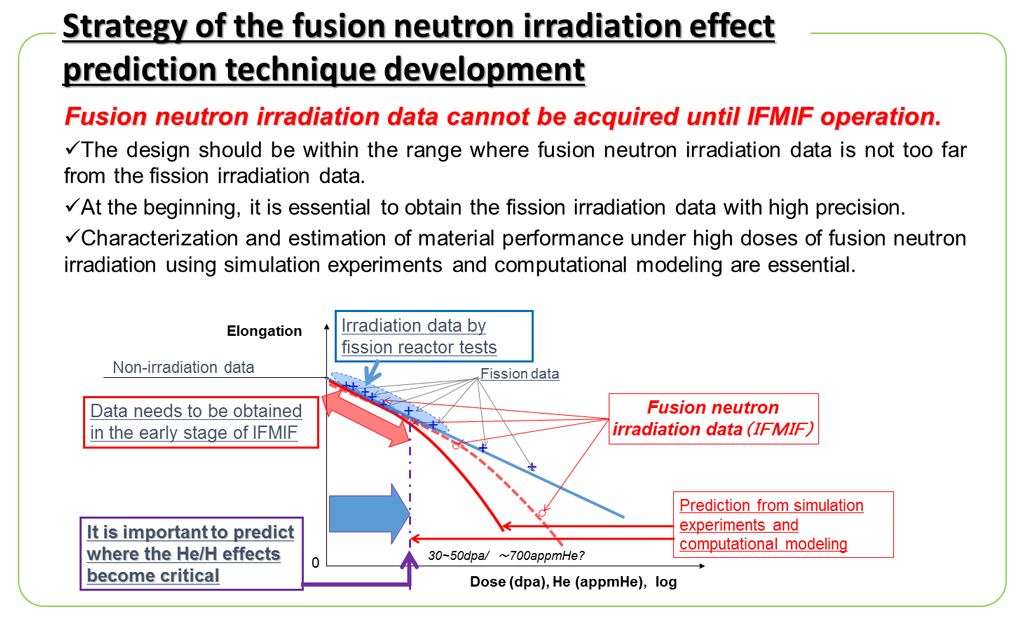

In a fusion reactor the materials for the components facing the core plasma, such as the blanket and divertor, will suffer from high-energy neutron loads and very high heat loads. When the materials encounter these loads, a lot of unique phenomena will occur in the materials. One of the most important phenomenon is called “radiation damage”, which is induced by high-energy neutron irradiation. The term “radiation damage” includes so called “displacement damage” that will produce disordered crystal structure inside materials and also “transmutation” that will produce different kinds of elements from the original composition. Both phenomena will lead to degradation of the original material properties that will eventually cause a failure of the components. This “radiation damage” itself is not a unique phenomenon for a fusion reactor environment but also is a common issue for materials used in fission nuclear reactors or satellites, where the components suffer from many kinds of irradiation. Each environment has different types of energetic particles and energies, so we have to conduct research under conditions specific to each environment. Therefore, in our department, we are conducting research to understand the mechanism on how the materials degrade their original properties under fusion neutron irradiation environment and also to evaluate the material integrity under neutron irradiations. In addition, we are also trying to develop and improve the materials with higher neutron irradiation resistance.

Main research activities

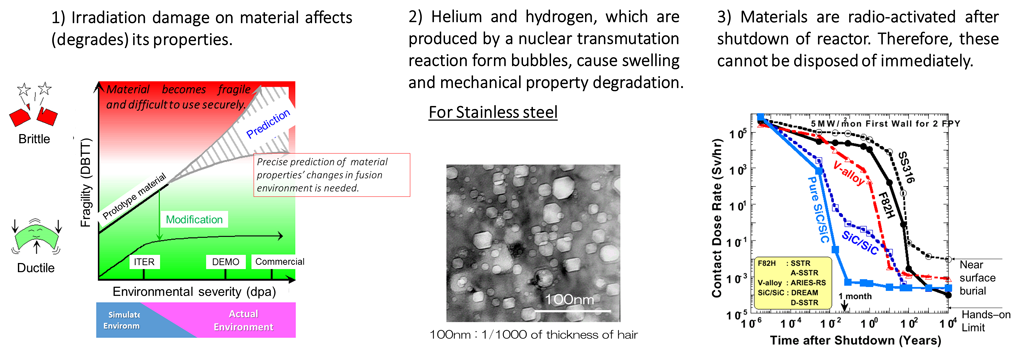

1. R&D on Reduced Activation Ferritic/Martensitic Steels

“Reduced Activation Ferritic/Martensitic Steel” is a type of steel developed on the basis of heat resistant steel G91 (Fe-9Cr-1MoVNb) to reduce activation after use in reactors. The term “reduced activation” means to replace an element that will transmute to an isotope with a long half-life under neutron irradiation with another element that will transmute to an isotope with a shorter half-life, so that the total activation will eventually attenuate much quicker than the original steel after use in reactors. In a fusion reactor, mainly steels will be used for the structure materials, as is the case in existing fission nuclear reactors, but in a fusion reactor environment, the energy of neutrons and the irradiation neutron doses on the materials will be much higher compared to the existing fission reactors. Therefore, we are planning to use ferritic/martensitic steels that have a higher resistance against irradiation. The important point is that the steels for a fusion reactor will be “reduced activation” steels. The reason why “reduced activation” is so important is that one of the principles of the development of a fusion reactor is to reduce radioactive waste as much as possible compared to existing fission nuclear reactors. Fundamentally in a fusion reactor, there will be no long-lived nuclear waste in contrast to the case of fission reactors, where a huge amount of nuclear waste comes from spent fuel. However, operation of a fusion reactor will produce a certain amount of short-lived radioactive waste from the materials. As a result, we are trying to reduce the amount of induced radioactivity in the materials to facilitate waste handling. On the other hand, even if we could reduce the radioactivity of the materials, if other material properties are spoiled, the materials developed will not be suitable for use in a fusion reactor. Therefore, we are developing steels with good characteristics both in irradiation resistance and low induced radioactivity. Furthermore, we are also conducting lifetime assessments of the ferritic/martensitic steels we have developed, to determine up to which neutron doses the materials keep their original properties and how we should use the materials without any failure of the components.

2. R&D on SiC/SiC composites

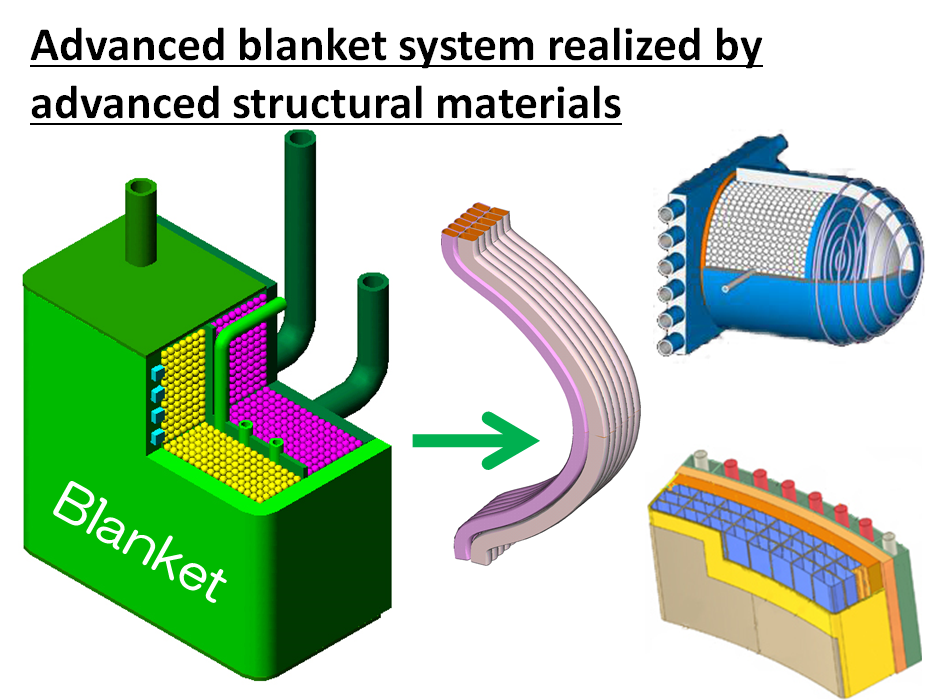

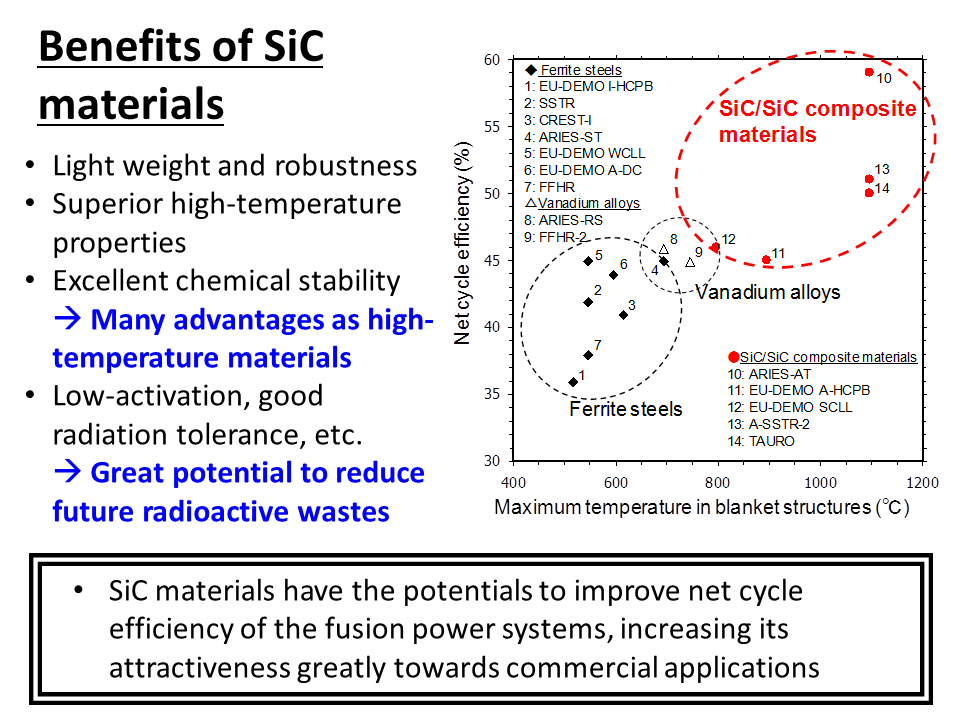

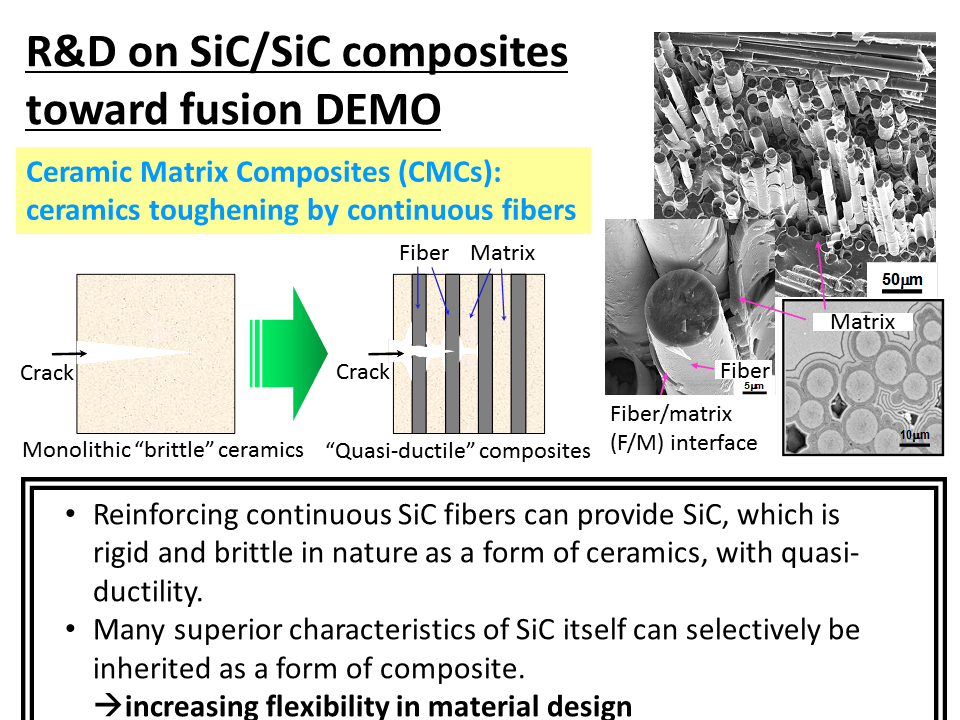

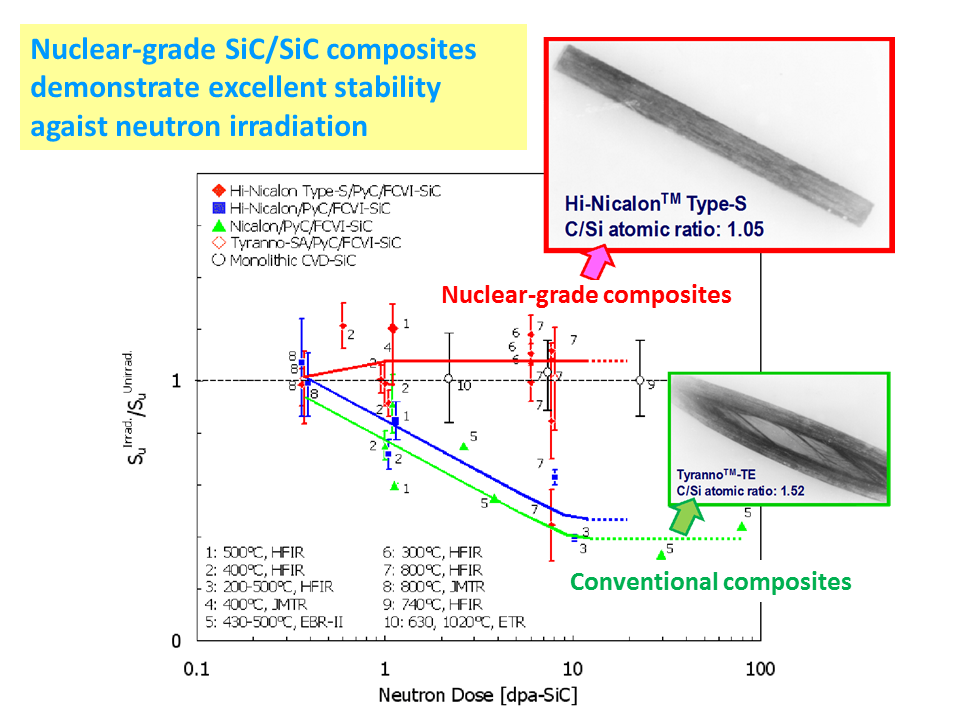

SiC is an attractive material because of its perceived merits of being lightweight, robustness, its mechanical and chemical stability at elevated temperatures etc. but in-nature “brittle”, easily resulting in fracture. SiC/SiC composites have improved their toughness by reinforcing with continuous SiC fibers (so-called “quasi-ductility”), without losing these inherent advantages of SiC itself. Of particular emphasis, good radiation tolerance has been demonstrated by applying high-crystallinity SiC constituents. A greatly improved net cycle efficiency of the fusion power system is expected by using this brand new composite material. In addition, due to inherent merits such as low-activation and low after-heat of SiC itself, the reduction of radioactive waste is significant. Presently, SiC/SiC composites are developed as one of the advanced materials to raise more attractiveness for the future fusion reactor system, e.g., a primary option of the advanced fusion blanket system for the commercial reactor. Toward practical applications, developing standards to appropriately and safely utilize composite materials, which are quite different from metals and ceramics, is very important. To establish the foundation of the standards for composites, their fundamental behavior and material properties are being researched. This class of composite materials has drawn interest to non-fusion industries; accident tolerant fuel in the light water reactor, rocket engine nozzles for aerospace vehicles, etc. The composites offer excellent examples of fundamental technologies promoted in fusion R&D showing the potential to share with various industries.